WIRE BRUSH ABRASIVES

Wheel Brushes

Scotch-Brite™ Radial Bristle Brushes

Features:

• Molded, abrasive filled bristles finish, polish, and deburr more effectively than wire brushes.

• Conformability allows abrasive to stay in contact with complex-shaped parts in robotic processing.

• Cleans with minimal pressure and contains no wire filaments for improved safety.

• Flexible bristles produce uniform finishes around protrusions, detail grooves, patterns, and other hard-to-reach areas.

Face Width: 1/2 in

| SKU | Dia. | Arbor Dia. | Bristle Material |

|---|---|---|---|

| 405-048011-27605 | 6 in | 1 in | Ceramic |

| 405-048011-27606 | 6 in | 1 in | Ceramic |

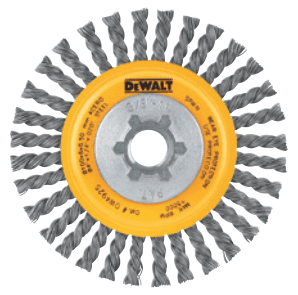

Stringer Bead Twist Knot Wheels

Features:

• Fastest cutting action.

• Designed for root and hot pass weld cleaning in pipe joining application.

• Tightly twisted for low flex, high impact brushing action.

Bristle Material: Carbon Steel

Face Width: 3/16 in

| SKU | Dia. | Bristle Diam | Arbor Diam. | Arbor Thread | No. of Knots |

|---|---|---|---|---|---|

| 419-82186 | 4 in | 0.02 in | 5/8 in | 5/8 in - 11 | 32 |

Crimped Wheel Brushes

Features:

• Provides very flexible brushing action.

• For light cleaning and deburring.

Arbor Diam: 1/4 in

Stem Diam: 1/4 in

Arbor Thread: 1/4 in

| SKU | Dia. | Bristle Material | Bristle Diam | Face Width |

|---|---|---|---|---|

| 102-CFX-3SPOP | 3 in | Stainless Steel | 0.014 in | 1/2 in |

| 102-BW-9220 | 3 in | Stainless Steel | 0.014 in | 5/8 in |

Knot Wheel Brushes

Features:

• Heavy-duty brushing action with some flexibility.

• Ideal for demanding cleaning applications on somewhat irregular surfaces.

• Use for general-purpose applications.

Arbor Diam: 5/8 in - 11

No. Of Knots: 20

Arbor Thread: 5/8 in - 11

| SKU | Dia. | Bristle Material | Bristle Diam | Face Width |

|---|---|---|---|---|

| 102-R4K58 | 4 in | Carbon Steel | 0.014 in | 4 in |

| 102-4K58 | 4 in | Carbon Steel | 0.014 in | 5/8 in |

| 102-4K58S | 4 in | Stainless Steel | 0.014 in | 5/8 in |

| 102-R4K58S | 4 in | Stainless Steel | 0.02 in | 1/2 in |

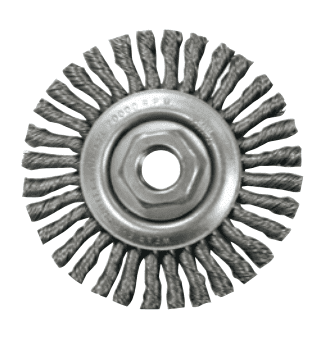

Standard Twist Knot Wheels

Features:

• Aggressive brushing action for general-purpose deburring, cleaning, and surface preparation applications.

• Weld preparation and cleaning, removing rust, scale and oxidation.

Arbor Diam: 5/8 in - 11

No. Of Knots: 24

Face Width: 1/2 in

Arbor Thread: 5/8 in - 11

| SKU | Dia. | Bristle Material | Bristle Diam |

|---|---|---|---|

| 102-6T58 | 6 in | Carbon Steel | 0.023 in |

Stringer Bead Wheel Brushes

Features:

• Very narrow face design primarily for weld cleaning and to access hard-to-reach areas.

Arbor Diam: 5/8 in - 11

Arbor Thread: 5/8 in - 11

| SKU | Dia. | Bristle Material | Bristle Diam | No. of Knots | Face Width |

|---|---|---|---|---|---|

| 102-4S58 | 4 in | Carbon Steel | 0.02 in | 30 | 4 in |

| 102-R4S58 | 4 in | Carbon Steel | 0.02 in | 30 | 4 in |

| 102-R6S58 | 6 in | Carbon Steel | 0.02 in | 48 | 3/6 in |

| 102-6S58 | 6 in | Carbon Steel | 0.02 in | 48 | 6 in |

| 102-7S58 | 7 in | Carbon Steel | 0.02 in | 56 | 3/6 in |

| 102-4S58S | 4 in | Stainless Steel | 0.02 in | 30 | 4 in |

| 102-R4S58S | 4 in | Stainless Steel | 0.02 in | 30 | 4 in |

| 102-BW-862 | 6 in | Stainless Steel | 0.02 in | 48 | 3/6 in |

| 102-6S58S | 6 in | Stainless Steel | 0.02 in | 48 | 6 in |

| 102-BW-855 | 5 in | Steel | 0.02 in | 38 | 3/16 in |

| 102-BW-760 | 6 in | Steel | 0.023 in | 24 | 1/2 in |

Crimped Wire Wheels-SSM Series

Features:

• Light to medium-duty cleaning.

• For removal of rust, paint and corrosion.

Stem Diam: 1/4 in

| SKU | Dia. | Bristle Material | Bristle Diam | Stem Diam. |

|---|---|---|---|---|

| 066-09551 | 3 in | Steel | 0.0104 in | 1/4 in |

| 066-09145 | 3 in | Steel | 0.014 in | 1/4 in |

Stringer Bead Knot Wire Wheels-STCM Series-Very Narrow Face

Features:

• Very narrow face designed for weld cleaning and hard-to-reach areas or narrow channels.

Face Width: 1/4 in

| SKU | Dia. | Bristle Material | Bristle Diam | No. of Knots | Arbor Diam. | Arbor Thread |

|---|---|---|---|---|---|---|

| 066-11215 | 4 in | Stainless Steel | 0.02 in | 32 | 5/8 in - 11 | 5/8 in - 11 |

| 066-12685 | 4 1/2 in | Carbon Steel | 0.02 in | 30 | 5/8 in - 11 | 5/8 in - 11 |

Stringer Wire Wheels

Features:

• High tensile, heat-treated carbon or stainless steel wire.

• Provides long-lasting aggressive brushing action.

• Internal holding plate construction provides reduced knot movement and increased control and brush life.

Arbor Diam: 5/8 in - 11

| SKU | Dia. | Bristle Material | Bristle Diam |

|---|---|---|---|

| 115-DW4925B | 4 in | Carbon | .02 in |

ADHESIVE PRODUCTS

Adhesive Product Accessor

Cartridge Mix Nozzles

Features:

• 1:1 epoxy adhesives (50ml).

• Mixing and delivery tool for Devcon.

| SKU | Capacity Volume |

|---|---|

| 230-14285 | 50 ml |

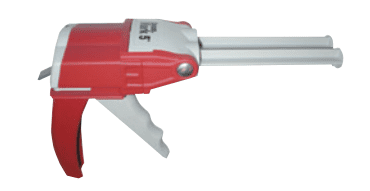

Mark 5™ Dispensing Systems

Features:

• 1:1 and for 10:1 ratio.

• Eliminates guesswork, excessive waste, and time associated with manually weighing and mixing two‑part adhesive systems.

• For dispensing and applying Devcon® adhesives for repair and assembly operations.

• Thoroughly mixes adhesives.

• Uses adhesive in 50‑ml Dev‑Pak™ cartridges.

| SKU | Type |

|---|---|

| 230-14280 | Applicator |

Adhesives & Glues

Scotch-Weld™ Neoprene High Performance Contact Adhesive 1357

Features:

• Gray‑Green contact adhesive can be used to bond most rubber, cloth, metal, wood, foamed glass, paper honeycomb, decorative plastic laminates and many other substrates.

• Meets requirements of MMM‑A‑121.

Chemical Compound: Polychloroprene

| SKU | Capacity Vol. | Color |

|---|---|---|

| 405-021200-19892 | 1 qt | Gray |

Scotchkote™ Liquid Epoxy Coatings

Features:

• Two‑part liquid epoxy kit suitable for brushing used for patching pipe coatings.

• It can be used as a patch material, a girth weld coating, a stand-alone coating for pipe rehabilitation, and in a wide variety of other field applications where corrosion protection of metal is required.

Tensile Strength: 4000 psi

Chemical Compound: 4‑Nonyl Phenol; C.I. Pigment Green 7; Color, Apha; Hydrous Magnesium Silicate; M‑Xylene‑. ALPHA.ALPH

| SKU | Capacity Vol. | Color |

|---|---|---|

| 500-175743 | 0.63 L; 0.31 L | Blue-Green |

Super Weatherstrip Adhesives

Features:

• Super weather‑strip adhesive is a strong, flexible, rubbery adhesive that can withstand vibration, oil, grease, and extreme temperature variations.

• It can be used to bond weather‑stripping to car doors, trunks, T‑tops, moon roofs and sunroofs.

• It provides the strength and rapid setting needed.

Chemical Compound: Neoprene Rubber

Working Time: <4 min

| SKU | Capacity Vol. | Color |

|---|---|---|

| 405-051135-08001 | 5 oz | Yellow |

Hi-Strength 90 Spray Adhesives

Features:

• Has high‑contact bond strength, one‑minute dry time, high temperature resistance, low misting, precise spray control and variable width spray pattern.

Adhesive Tensile Shear: 600 psi

Tensile Strength: 600 psi

Chemical Compound: Acetone

Working Time: 1 min to 10 min

| SKU | Capacity Vol. | Color |

|---|---|---|

| 405-021200-30023 | 17.6 oz | Clear |

Multi-Purpose 27 Spray Adhesives

Features:

• Provides professional, industrial strength for demanding applications at an economical price.

• Includes a versatile adhesive that bonds a wide range of lightweight materials.

• Offers a fast, aggressive tack for a quick bond that reduces set time.

Adhesive Tensile Shear: 200 psi

Chemical Compound: Acetone; Cyclohexane; Isobutane; Propane

Packing Type: Aerosol Can

| SKU | Capacity Vol. | Color |

|---|---|---|

| 405-051111-07832 | 20 fl oz | White |

Neoprene High Performance Contact Adhesive 1357

Features:

• High performance contact adhesive that provides a long bonding range and excellent initial strength.

• Adheres exceptionally well to many decorative plastic laminates, paper honeycomb, rubber, cloth, metal, wood and foamed glass.

Test & Approvals: Meets Requirements of MIL‑A‑21366A and MMM‑A‑121

Packing Type: Tube

| SKU | Capacity Vol. | Color |

|---|---|---|

| 405-021200-19887 | 5 oz | Gray-Olive |

Nitrile High Performance Plastic Adhesive 1099

Features:

• Fast drying adhesive with good resistance to plasticizer migration.

• High strength and resistance to weathering, water, oil and many solvents.

Chemical Compound: Nitrile Rubber

Packing Type: Tube

| SKU | Capacity Vol. | Color |

|---|---|---|

| 405-021200-19808 | 5 oz | Light Tan |

Scotch-Grip™ Rubber & Gasket Adhesive

Features:

• Versatile, solvent based high performance adhesive with low viscosity for easy application.

• Good oil and heat resistance.

• Is commonly used for bonding most rubber and gasket material.

Packing Type: Tube

| SKU | Capacity Vol. | Color | Working Time |

|---|---|---|---|

| 405-021200-19718 | 5 oz | Brown | 15 min |

| 405-021200-19868 | 5 oz | Yellow | 12 min |

Scotch-Weld™ Two-Part Epoxy Adhesives

Features:

• One‑part cyanoacrylate adhesives apply from the container and rapidly reach handling strength at room temperature without a catalyst.

• Bonds achieve 80 percent of full strength in an hour.

• A single drop per square inch can bond many plastics, rubber, metal and more with tensile strength up to 5,000 psi.

Test & Approvals: Meets Corrosion Requirements of MIL‑S‑461633

| SKU | Capacity Vol. | Color | Chemical Compound | Packing Type |

|---|---|---|---|---|

| 405-021200-22648 | 1.7 oz | Clear | Ethyl | Duo-Pak |

| 405-021200-87195 | 1.7 oz | Clear | — | Duo-Pak |

| 405-021200-82236 | 37 ml | Clear | Ethyl | Duo-Pak |

Super 77™ Multi-Purpose Spray Adhesives

Features:

• Multi-purpose spray adhesive bonds to many surfaces.

• Great for use in home, office and craft projects.

• Versatile, quick drying and transparent.

• Fast, permanent bond provides quick results.

• Aggressive tack provides high initial grab with enough time to position materials properly.

• Industrial sized can provides high coverage.

• Resists dripping or running when used in vertical applications.

Chemical Compound: Synthetic Elastomer

| SKU | Capacity Vol. | Color | Tensile Strength | Working Time |

|---|---|---|---|---|

| 405-021200-21210 | 16.75 oz | Clear | 300 psi | 15 sec to 15 min |

| Low VOC <25% | ||||

| 405-051111-97956 | 24 oz | Clear | 300 psi | 15 sec to 30 min |

High Strength Adhesives

Features:

• CA VOC Compliant formula.

• Flexible and waterproof with high sheer and peel strength.

• High strength industrial use adhesive for extra‑strong bonding of materials to a wide variety of surfaces.

• Top performer on porous surfaces with low soak‑In.

• Very fast dry‑time with 1‑minute tack time in a web‑fan spray pattern.

Chemical Compound: Hexane; Hydrocarbon; Acetone

Working Time: 1 min Tacky; 5 min Open

Packing Type: Aerosol Can

| SKU | Capacity Vol. | Color |

|---|---|---|

| 205-C8190 | 12 oz | Straw |

1-Minute® Gel Epoxy

Features:

• Fills gaps.

• Fast‑curing without fixturing.

• Non‑sagging on vertical surfaces.

Test & Approvals: Adhesive tensile shear strength Tested by ASTM D1002 with an overlap shear run at 0.005” bond line thickness

Adhesive Tensile Shear: 1,600 psi

Working Time: 45 sec

Dielectric Strength: 490 V/mil

Packing Type: Dev‑Pak™

| SKU | Capacity Vol. | Chemical Compound | Color |

|---|---|---|---|

| 230-14277 | 50 ml | Epoxy | Amber |

10 Minute™ Epoxy

Features:

• Flexible epoxy provides excellent adhesion to metals and superior peel, impact, and chemical resistance.

• High shear strength.

• Excellent chemical resistance to oils, hydrocarbons, and fuels.

• Self leveling liquid for encapsulating components.

• Bonds dissimilar substrates.

• Provides good gap fill.

Adhesive Tensile Shear: 2,400 psi

Working Time: 10 min

Dielectric Strength: 800 V/mil

Packing Type: Dev‑Pak™

| SKU | Capacity Vol. | Color |

|---|---|---|

| 230-14255 | 50 ml | Black |

2 Ton® Clear Epoxy

Features:

• Extremely strong, medium‑cure adhesive.

• Self‑Leveling after application.

• Works to fill poorly mated joining surfaces, while providing adhesion.

• Water‑resistant formula.

• Cures without shrinking.

• Produces strong, rigid bond to metal, ceramics, wood, concrete, glass in any combination.

Adhesive Tensile Shear: 2,250 psi

Dielectric Strength: 600 V/mil

| SKU | Capacity Vol. | Color | Chemical Compound | Packing Type |

|---|---|---|---|---|

| 230-14310 | 25 ml | Clear; White | Epoxy | Dev-Tube™ |

| 230-14260 | 50 ml | Clear; White | Epoxy | Dev-Pak™ |

5 Minute® Epoxies

Features:

• Provides a strong bond between rigid, durable substrates ‑ great for use with glass, metal, ceramics, concrete and wood in all combinations.

Adhesive Tensile Shear: 1,400 psi

Gap Fill: 1/4 in

Working Time: 3‑6 min

Dielectric Strength: 490 V/mil

| SKU | Capacity Vol. | Color | Chemical Compound | Packing Type |

|---|---|---|---|---|

| 230-14630 | 1 gal | Light Amber | Epoxy | Dev-Pak™ |

| 230-14200 | 15 oz | Light Amber | Epoxy | Dual Bottle |

| 230-14210 | 2 1/2 oz | Light Amber | Epoxy | Dual Tube |

| 230-14250 | 25 ml | Light Amber | Epoxy | Dev-Tube™ |

| 230-14270 | 50 ml | Light Amber | Epoxy | Dev-Pak™ |

5 Minute® Epoxy Gels

Features:

• Fast‑curing, thixotropic, nonmigrating gel adhesive with excellent gap filling properties.

• Non‑sagging adhesive is ideal for use on vertical surfaces.

• Fills gaps to .25 inch.

Adhesive Tensile Shear: 2,500 psi

Gap Fill: 1/4 in

Chemical Compound: Epoxy

Working Time: 4‑7 min

Dielectric Strength: 440 V/mil

| SKU | Capacity Vol. | Color | Packing Type |

|---|---|---|---|

| 230-14240 | 25 ml | Opaque | Dual Syringe Tube |

| 230-14265 | 50 ml | Opaque | Dev-Pak™ |

Aluminum Liquid (F-2)

Features:

• Aluminum‑filled pourable epoxy for making molds, patterns, and holding fixtures.

• Can be machined, drilled, or tapped.

• Low viscosity provides accurate reproduction of mold details and of delicate or intricate parts.

• Qualifies under MMM‑A‑1754.

• 75‑minute working time.

Test & Approvals: Chemical resistance was tested by immersion for 30 days at 75 °F, after 7 days room temperature cure

Adhesive Tensile Shear: 2,700 psi

Tensile Strength: 5,000 psi

Compressive Strength: 9,820 psi

Gap Fill: 1 in

Chemical Compound: Epoxy

Working Time: 75 min

Dielectric Strength: 100 V/mil

Packing Type: Kit

| SKU | Capacity Vol. | Color |

|---|---|---|

| 230-10710 | 1 lb | Aluminum |

| 230-10720 | 3 lb | Aluminum |

Brushable Ceramic

Features:

• When applied in a 15‑20 mil coating, this low‑viscosity, alumina‑filled, brushable epoxy compound provides a smooth, protective barrier against wear, abrasion, corrosion, erosion, and chemical attack.

• Low‑friction surface reduces turbulence, wear, and cavitations.

• Outstanding chemical resistance to acids, solvents, and alkalis.

• 3 colors (red blue white) to insure uniform coating.

• Red and white formulas are acceptable for use in meat and poultry plants.

• White is NSF‑certified for use in potable water applications.

• 40‑minute working time (Red, Blue).

• 21‑minute working time (White).

Test & Approvals: Chemical resistance was tested by immersion for 30 days at 75 °F, after 7 days room temperature cure; Accepted for Use in meat and poultry plants under the former USDA Food Safety and Inspection Service Product Approval Program; ANSI; NSF

Adhesive Tensile Shear: 2,000 psi

Tensile Strength: 3,800 psi

Compressive Strength: 15,200 psi

Working Time: 40 min

Dielectric Strength: 382 V/mil

Packing Type: Kit

| SKU | Capacity Vol. | Chemical Compound | Color |

|---|---|---|---|

| 230-11765 | 2 lb | Epoxy | Blue |

| 230-11760 | 2 lb | Epoxy | Red |

Flexane® 80 Liquid

Features:

• Medium‑viscosity urethane fills voids completely.

• Faithfully reproduces mold detail, and cures to semi‑rigid rubber.

• Ten‑hour demolding time.

Test & Approvals: Dielectric strength tested according to ASTM D149; Tensile strength tested according to ASTM D412

Tensile Strength: 2,100 psi

Working Time: 30 min

Dielectric Strength: 350 V/mil

Packing Type: Can

| SKU | Capacity Vol. | Chemical Compound | Color | Gap Fill |

|---|---|---|---|---|

| 230-15800 | 1 lb | Polyurethane | Black | .25” |

| 230-15810 | 10 lb | Polyurethane | Black | .25” |

Flexane® 94 Liquid

Features:

• Requires only a five hour demolding time.

• Low‑viscosity urethane cures to rigid rubber.

• Harder material than Flexane® 80 Liquid.

Test & Approvals: Dielectric strength tested according to ASTM D149; Tensile strength tested according to ASTM D412

Tensile Strength: 2,800 psi

Gap Fill: 1/4 in

Working Time: 10 min

Dielectric Strength: 350 V/mil

Packing Type: Kit

| SKU | Capacity Vol. | Chemical Compound | Color |

|---|---|---|---|

| 230-15250 | 1 lb | Polyurethane | Black |

Floor Patch™

Features:

• All‑purpose concrete patching compound with a compression strength of 8,000 psi, three times the typical strength of concrete.

• Excellent adhesion to concrete, brick, masonry, metal or wood surfaces.

• Excellent resistance to water, oils, solvents, and alkalis.

Test & Approvals: Chemical resistance was tested by immersion for 30 days at 75 °F, after 7 days room temperature cure

Adhesive Tensile Shear: 3,500 psi

Compressive Strength: 8,000 psi

Gap Fill: 1/4 in

Working Time: 45 min

| SKU | Capacity Vol. | Chemical Compound | Color |

|---|---|---|---|

| 230-13120 | 40 lb | Epoxy | Gray |

HVAC Repair (Special F)

Features:

• Aluminum‑filled epoxy adhesive for repairs to copper coils in compressors.

• Bonds to aluminum and other metals, ceramics, woods, concrete or glass.

• Hardens to a rigid bond that can be ground, drilled, or tapped.

Test & Approvals: Chemical resistance was tested by immersion for 30 days at 75 °F, after 7 days room temperature cure

Compressive Strength: 12,700 psi

Dielectric Strength: 350 V/mil

| SKU | Capacity Vol. | Chemical Compound | Color |

|---|---|---|---|

| 230-19770 | 6 1/2 oz | Epoxy | Grey |

Plastic Steel® Liquid (B)

Features:

• 45‑minute working time.

• Can be machined to close tolerances.

• Hardens in about an hour.

• Low viscosity and high compressive strength.

Test & Approvals: Chemical resistance was tested by immersion for 30 days at 75 °F, after 7 days room temperature cure; Qualifies under Mil Spec MMM‑A‑1754

Adhesive Tensile Shear: 2,800 psi

Tensile Strength: 4,900 psi

Compressive Strength: 10,200 psi

Working Time: 45 min

Dielectric Strength: 30 V/mil

| SKU | Capacity Vol. | Chemical Compound | Color |

|---|---|---|---|

| 230-10210 | 1 lb | Epoxy | Dark Grey |

Plastic Welder™

Features:

• Bonds dissimilar substrates as well as unprepared surfaces; great for engineered plastics, metals, ceramics, concrete, polyesters, polycarbonate, wood and more.

Test & Approvals: Peel strength tested according to ASTM D1876‑61P; Resistance tested by immersion of bonded steel lap joints for 2 weeks in antifreeze, jet fuel, 10% and 50% sulfuric acid, and 10% and 20% potassium hydroxide, and by immersion for 2 months in gasoline at 72 °F; Shear strength tested according to ASTM D1002; Compression shear strength tested according to ASTM D3931; Impact resistance tested according to ASTM D950

Adhesive Tensile Shear: 3,500 psi

Working Time: 4‑6 min

| SKU | Capacity Vol. | Chemical Compound | Gap Fill |

|---|---|---|---|

| 230-14300 | 25 ml | Methyl Methacrylate | 1/8 in |

Underwater Repair Putty (UW)

Features:

• Penetrates wetness to bond securely to steel, iron, aluminum, brass, bronze, concrete, wood, and some plastics.

• Invaluable for use in pulp and paper mills, wastewater treatment plants, and marine environments.

• Eliminates the need for substrate to be thoroughly dry before repair.

• Easy‑to‑mix and apply.

• Cures in temperatures as low as 40 °F.

Test & Approvals: Chemical resistance was tested by immersion for 30 days at 75 °F, after 7 days room temperature cure

Adhesive Tensile Shear: 2,685 psi

Compressive Strength: 5,625 psi

Gap Fill: 1/4 in

Chemical Compound: Epoxy

Working Time: 45 min

Dielectric Strength: 150 V/mil

Packing Type: Can

| SKU | Capacity Vol. | Color |

|---|---|---|

| 230-11800 | 1 lb | Gray |

Wear Guard™ High Load

Features:

• Alumina ceramic bead‑filled epoxy system with outstanding abrasion resistance for severe service conditions with particulate greater than 1/8”.

• Will not sag on overhead or vertical surfaces.

• Exceptional resistance to a wide range of acids, bases, saturated salt solutions, oils, and many other chemicals.

• Ideal for repairing scrubbers, ash handling systems, pipe elbows, screens, and chutes.

• 30‑minute working time.

Test & Approvals: Chemical resistance was tested by immersion for 30 days at 75 °F, after 7 days room temperature cure

Adhesive Tensile Shear: 1,474 psi

Tensile Strength: 4,210 psi

Compressive Strength: 11,000 psi

Gap Fill: 3/4 in

Chemical Compound: Epoxy

Working Time: 30 min

Dielectric Strength: 340 V/mil

Packing Type: Kit

| SKU | Capacity Vol. | Color |

|---|---|---|

| 230-11490 | 30 lb | Grey |

Wear Resistant Putty WR-2

Features:

• Bonds to steel, iron, aluminum, ceramic, concrete, brass, and some plastics.

Test & Approvals: Chemical resistance was tested by immersion for 30 days at 75 °F, after 7 days room temperature cure

Adhesive Tensile Shear: 2,200 psi

Tensile Strength: 4,300 psi

Compressive Strength: 9,800 psi

Gap Fill: 1/4 in

Working Time: 1 hr

Dielectric Strength: 400 V/mil

| SKU | Chemical Compound | Capacity Vol. | Color |

|---|---|---|---|

| 230-11410 | Epoxy | 1 lb | Dark Gray |

Zip Patch™

Features:

• Hardens to a tough, durable waterproof finish in minutes.

• Excellent adhesion to iron, steel, stainless steel, titanium, fiberglass, aluminum, wood, ceramics, composites, acrylics, PVC, and most other plastics.

Test & Approvals: Chemical resistance was tested by immersion for 2 weeks at 42 °C after 7 days cure at 75 °F

Adhesive Tensile Shear: 2,400 psi

Tensile Strength: 10,000 psi

Dielectric Strength: 250 V/mil

| SKU | Chemical Compound | Color |

|---|---|---|

| 230-11500 | Epoxy | Brown |

Strong Steel Stick Renewal Composite

Features:

• Hardens like steel in 20 minutes.

• Permanently fill gaps & holes in metal, concrete, wood, fiberglass & ceramics.

• Can be used for underwater repairs.

Adhesive Tensile Shear: 800 psi

Tensile Strength: 900 psi

Compressive Strength: 8,000 psi

Chemical Compound: Epoxy

Dielectric Strength: 300 V/mil

| SKU | Capacity Vol. | Color |

|---|---|---|

| 428-60159 | 4 oz | Black; Gray |

Heavy-Duty Adhesive Spray

Features:

• For temporary or permanent bonding of uneven or porous surfaces and weighted materials.

• Waterproof, flexible, transparent and nonstaining.

• Non‑ozone depleting.

Packing Type: Aerosol Can

| SKU | Capacity Vol. | Color |

|---|---|---|

| 019-1002035 | 12 oz | Clear |

357 Premium Web Spray Adhesives

Features:

• Designed for temporary and permanent bonding.

• Creates strong bond for normal hard to bond surfaces.

• Fast skin, fast grab, low soak‑in.

Working Time: 1 min to 1 h

Packing Type: Aerosol Can

| SKU | Capacity Vol. | Color |

|---|---|---|

| 573-1421892 | 19.6 fl oz | Water White |

ZipGrip® GPE 3 Cyanoacrylate Adhesives

Features:

• For repairing O‑rings, rubber weatherstripping, gaskets, and plastic parts.

• For fixturing parts.

• Permanently bonds metal to metals, rubber, and plastics.

Adhesive Tensile Shear: 2,500 psi

Gap Fill: 0.003 in

Chemical Compound: Cyanoacrylate

Working Time: Fixtures in seconds

Dielectric Strength: 295 V/mil

Packing Type: Bottle

| SKU | Capacity Vol. | Color |

|---|---|---|

| 230-70144 | 14 gm | Clear |

ZipGrip® GPE 30 Cyanoacrylate Adhesives

Features:

• For repairing O‑rings, rubber weatherstripping, gaskets, and plastic parts.

• For fixturing parts.

• Permanently bonds metal to metals, rubber, and plastics.

• Fixtures in seconds on metal plastic and rubber.

Test & Approvals: A‑A‑3097, Type II, Class 1

Adhesive Tensile Shear: 3,200 psi

Gap Fill: 0.004 in

Chemical Compound: Cyanoacrylate

Working Time: Fixtures in seconds

Dielectric Strength: 11.6 kV/mm

| SKU | Capacity Vol. | Color |

|---|---|---|

| 230-70350 | 1 oz | Clear |

Putty

Minute Mend™ Epoxy Putties

Features:

• Specially formulated to bond to both wet and dry surfaces and can be applied underwater.

• 2‑part epoxy putty packaged in a 1‑piece stick.

• Ready to use in less than one minute.

• Can be tapped, sawed, drilled, machined, stained, or painted.

Test & Approvals: Meets 1998 USDA guidelines for use in meat and poultry plants; Dielectric strength tested by ASTM D‑149

Specific Gravity: 1.98

Stress Resistance: 800 psi (tensile) ‑ 1,000 psi (tensile)

Hardness: 65.0 Shore D

Applications: Multi‑Purpose

Applicable Materials: Ceramic; Concrete; Fiberglass; Glass; Plastic; Steel; Wood; Aluminum

Full Cure Time @ Temp.: 24 h @ 77 °F

Dielectric Strength: 300.0 V/mil

Resistance: Ester; Alcohol; Ketone; Salt; Halogenated Hydrocarbon

| SKU | Temp. Range | Color |

|---|---|---|

| 125-14070 | 250.0 °F | Gray |

Aluminum Putty F

Features:

• Aluminum‑filled epoxy putty for dependable non‑rusting repairs to aluminum castings, machinery, and equipment widely used in HVAC applications.

• Excellent resistance to chlorofluorocarbons.

• Bonds to aluminum and many other metals.

• Fills porosity in aluminum castings.

• Can be machined drilled or tapped using conventional metalworking tools.

• Qualifies under DOD‑C‑24176B/(SH), Type II.

• 60‑minute working time.

Test & Approvals: Chemical resistance was tested by immersion for 30 days at 75 °F, after 7 days room temperature cure; Qualified per MIL‑DOD‑C‑24176B.

Specific Gravity: 1.58

Hardness: 85.0 Shore D

Applications: Multi‑Purpose

Applicable Materials: Aluminum; Most Metals

Full Cure Time @ Temp.: 16 h @ 75 °F

Dielectric Strength: 100.0 V/mil

Resistance: Chlorinated Solvents; Hydrochloric Acid‑10%; Kerosene

| SKU | Temp. Range | Color |

|---|---|---|

| 230-10610 | 250.0 °F | Aluminum |

Bronze Putty (BR)

Features:

• Bronze‑filled epoxy putty for repairing bronze and brass bushings, shafts, castings, and parts.

• Repairs and rebuilds areas where brazing would be undesirable or impossible.

• Bonds securely to bronze alloys, brass, copper, and ferrous metals.

• Uses conventional metalworking tools to machine, drill, tap, or grind.

• 35‑minute working time.

Test & Approvals: Chemical resistance was tested by immersion for 30 days at 75 °F, after 7 days room temperature cure

Specific Gravity: 2.23

Hardness: 85.0 Shore D

Applications: Bronze Parts/Equipment

Applicable Materials: Bronze; Most Metals

Full Cure Time @ Temp.: 16 h @ 75 °F

Dielectric Strength: 25.0 V/mil

Resistance: Ammonia; Kerosene; Sodium Hydroxide‑10%; Toluene

| SKU | Temp. Range | Color |

|---|---|---|

| 230-10260 | 250.0 °F | Bronze |

Carbide Putty

Features:

• Silicone carbide‑filled epoxy putty for economical protection against wear and abrasion.

• Excellent abrasion resistance in aggressive industrial environments.

• Handles particulates less than 1/16.

• 50‑minute working time.

Test & Approvals: Chemical resistance was tested by immersion for 30 days at 75 °F, after 7 days room temperature cure

Specific Gravity: 1.7

Hardness: 85.0 Shore D

Applications: Multi‑Purpose

Applicable Materials: Most Metals

Full Cure Time @ Temp.: 16 h @ 75 °F

Dielectric Strength: 200.0 V/mil

Resistance: 1,1,1‑Trichloroethane; Ammonia; Gasoline (Unleaded); Potassium Hydroxide 40%; Sodium Hydroxide 50%; Sodium Hypochlorite; Toluene; Trisodium Phosphate

| SKU | Temp. Range | Color |

|---|---|---|

| 230-10050 | 250.0 °F | Grey |

Ceramic Repair Putty

Features:

• Trowelable, alumina‑filled epoxy compound for rebuilding, smoothing, and protecting processing equipment exposed to corrosion, erosion, cavitation, chemicals and acids.

• Excellent for filling voids and rebuilding metal castings.

• 25‑minute working time.

• Qualifies under Mil Spec DOD‑C‑24176B(SH) Type I II.

Test & Approvals: Shear Strength Tested According to ASTM D1002; Cured Shrinkage Tested by ASTM D2566; Compression Strength Tested According to ASTM D695; Dielectric Strength Tested According to ASTM D149; Cured Hardness Tested According to ASTM D‑2240; Chemical Resistance was Tested by Immersion for 30 Days at 75 °F, After 7 Days Room Temperature Cure

Specific Gravity: 1.69

Hardness: 90.0 Shore D

Applications: Multi‑Purpose

Applicable Materials: Most Metals

Full Cure Time @ Temp.: 16 h @ 75 °F

Dielectric Strength: 370.0 V/mil

Resistance: Sodium Hypochlorite‑5%; Triosodium Phosphate‑5%; Trisodium Phosphate‑5%; Hydrochloric Acid‑10%

| SKU | Temp. Range | Color |

|---|---|---|

| 230-11700 | 350.0 °F | Dark Blue |

Flexane® 80 Putty

Features:

• Trowelable urethane for repairing and lining process equipment exposed to wear, impact, abrasion, vibration, and expansion/contraction.

• Mixes easily and trowels on smoothly.

• Cures to a tough, medium‑hard rubber.

• Flexane® Primers are recommended for maximum adhesion to metal, rubber, and concrete surfaces.

• 20‑minute working time.

Test & Approvals: Dielectric strength tested according to ASTM D149; Tensile strength tested according to ASTM D412

Specific Gravity: 1.1 @ 77 °F

Hardness: 87.0 Shore A

Applications: Trowelable Repair

Applicable Materials: Concrete; Fiberglass; Most Metals; Rubber; Wood

Full Cure Time @ Temp.: 7 d @ 75 °F

Dielectric Strength: 350.0 V/mil

Resistance: Tear; Aluminum Sulfate 10%; Hydrochloric 36%; Potassium Hydroxide 40% Phosphoric 10%; Sodium Hydroxide 50%

Packing Type: Can

| SKU | Temp. Range | Color |

|---|---|---|

| 230-15820 | 120.0 °F; 180.0 °F | Black |

Plastic Steel® 5 Minute® Putty (SF)

Features:

• Fast‑curing, steel‑filled epoxy for emergency repairs at temperatures as low as 40 °F.

• Cures to a tough, steel‑filled material.

• Can be machined, drilled, tapped, or sanded.

• 5‑minute working time.

Specific Gravity: 2.8

Hardness: 85.0 Shore D

Applications: Multi‑Purpose

Applicable Materials: Concrete; Most Metals

Full Cure Time @ Temp.: 1 h @ 75 °F

Dielectric Strength: 35.0 V/mil

Resistance: Kerosene; Ammonia; Water; Leaded Petrol; Saltwater

Packing Type: Kit

| SKU | Temp. Range | Color |

|---|---|---|

| 230-10240 | 200.0 °F | Dark Grey |

Plastic Steel® Putty (A)

Features:

• The original metal‑filled epoxy putty.

• Used for hundreds of routine maintenance, production, and tooling applications.

• Bonds to most metals concrete and some plastics.

• Cures at room temperature and forms a tough durable metallic mass that can be drilled, tapped, machined, or painted.

• Excellent resistance to oil gasoline water and many chemicals.

• Ideal for patching and repairing areas where welding or brazing would be undesirable or impossible.

• 45‑minute working time.

Test & Approvals: Chemical resistance was tested by immersion for 30 days at 75 °F, after 7 days room temperature cure; MIL; Qualifies under DOD‑C‑24176B(SH), Type I

Specific Gravity: 2.8

Hardness: 85.0 Shore D

Applications: Multi‑Purpose

Applicable Materials: Concrete; Most Metals

Full Cure Time @ Temp.: 16 h @ 75 °F

Dielectric Strength: 30.0 V/mil

Resistance: Chlorinated Solvents; Hydrochloric Acid‑10%; Kerosene; Water; Leaded Petrol; Propylene Glycol; Mineral Spirits; Sulfuric Acid‑10%

| SKU | Temp. Range | Color | Packing Type | Wt. |

|---|---|---|---|---|

| 230-10110 | 250.0 °F | Dark Grey | Can | 1.33 lb |

| 230-10120 | 250.0 °F | Dark Grey | Kit | 5.33 lb |

Stainless Steel Putty (ST)

Features:

• Stainless steel‑filled epoxy putty for patching, repairing, and rebuilding stainless steel food processing equipment.

• Bonds to ferrous and non‑ferrous metals.

• Non‑rusting.

• NSF certified for potable water applications.

• Acceptable for use in meat and poultry plants.

• 58‑minute working time.

Test & Approvals: Chemical resistance was tested by immersion for 30 days at 75 °F, after 7 days room temperature cure; Certified for Potable Water Application

Specific Gravity: 3.1

Hardness: 85.0 Shore D

Applications: Multi‑Purpose

Applicable Materials: Stainless Steel

Full Cure Time @ Temp.: 16 h @ 75 °F

Dielectric Strength: 30.0 V/mil

Resistance: Chlorinated Solvents; Hydrochloric Acid‑10%

Packing Type: Can

| SKU | Temp. Range | Color |

|---|---|---|

| 230-10270 | 250.0 °F | Grey |

Titanium Putty

Features:

• High‑tech, titanium‑reinforced epoxy putty for making repairs that can be precision machined.

• Resistance to chemicals and most acids, bases, solvents, and alkalis.

Test & Approvals: Qualifies under Mil Spec DOD‑C‑24176(SH) Type I & II

Color: Gray

Temp. Range: 350 °F

Applications: Multi‑Purpose

| SKU | Specific Gravity | Hardness | Full Cure Time @ Temp. | Dielectric Strength | Packing Type |

|---|---|---|---|---|---|

| 230-10760 | 2.5 | 87 Shore D | 7 d @ 75 °F | 56.0 V/m | Can |

| 230-10770 | 2.36 | 87 Shore D | 4 h @ 75 °F | 56.0 V/mil | Tub |

SEALING PRODUCTS

Caulk Guns

Caulking Guns

Features:

• Half‑barrel caulk gun with smooth rod and quick‑release mechanism.

• Suitable for light‑to‑medium applications of glazing, sealing or caulking.

• Holds most standard cartridges.

| SKU | Thrust Ration |

|---|---|

| 630-3984 | 10.1 |

| 630-3986 | 10.7 |

| 630-3985 | 7.1 |

Retaining Compounds

Bearing Mount for Close Fits

Features:

• Designed to bond non‑threaded, cylindrical metal assemblies by filling the voids between close‑fitting metal parts.

• Seal joints against leakage and prevents fretting and corrosion.

Color: Green

Gap Fill: 0.005 in

Temp. Range: ‑65 °F ‑ 300 °F

Shear Strength: 3,000 psi

Fix Cure Time @ Temp.: 10 min @ 72 °F

Full Cure Time @ Temp.: 24 h @ 72 °F

Curing Method: Anaerobic

Resistance: Diesel Fuel; Hydraulic Fluid; Leakage; Moisture; Vibration Loosening

| SKU | Capacity Vol. | Packing Type |

|---|---|---|

| 230-60950 | 50 ml | Bottle |

Bearing Mount for Relaxed Fits

Features:

• Designed to bond non‑threaded, cylindrical metal assemblies by filling the voids between close‑fitting metal parts.

• Seal joints against leakage and prevents fretting and corrosion.

Test & Approvals: NSF

Color: Green

Gap Fill: 0.015 in

Temp. Range: ‑65 °F ‑ 300 °F

Shear Strength: 3,800 psi

Fix Cure Time @ Temp.: 10 min @ 72 °F

Full Cure Time @ Temp.: 24 h @ 72 °F

Curing Method: Anaerobic

Applications: Retaining

Resistance: Diesel Fuel; Hydraulic Fluid; Leakage; Moisture; Vibration Loosening

| SKU | Capacity Vol. | Packing Type |

|---|---|---|

| 230-68050 | 50 ml | Bottle |

Sealants

Minimal Expanding Foam Sealants

Features:

• Designed to fill, seal, bond, retrofit, insulate, and deaden sound in and around cracks and cavities.

• Forms a permanent, waterproof and airtight bond to masonry, wood, glass, metal, and most plastics.

• Stops drafts, dust, moisture, insects and rodents.

• When cured, foam can be sanded, painted or stained.

• The low expansion formula expands 50% when fully cured.

• Cured foam insulates to R‑5 for each inch of foam.

• Foam and propellant are non‑flammable.

• Convenient 360º valve ‑ can be sprayed from any position.

Test & Approvals: UL

Temp. Range: ‑200 °F ‑ 200 °F

Color: Off‑White

Resistance: Waterproof; Airtight

Full Cure Time @ Temp.: 12 h @ 77 °F; 24 h @ 77 °F

Specific Gravity: 1.2

VOC: 2.9%, 35 g/L

| SKU | Capacity | Packing Type |

|---|---|---|

| 125-14077 | 12 oz | Aerosol Can |

RTV Silicone Adhesive/Sealants

Features:

• Clear ‑ Forms a barely visible water‑tight seal.

• White ‑ Designed for high moisture, indoor/outdoor applications.

• Blue ‑ Heavy-duty industrial gasket sealant.

• Red ‑ High temperature, low odor, non‑corrosive gasket sealant.

• Seal, bond, waterproof and protect.

Test & Approvals: Meets MIL‑A‑46106B, Group 1, Type 1 when fully cured and washed; Meets ASTM C‑920 when fully cured and washed; Meets TT‑S‑001543A Class A when fully cured and washed; Meets CAN/CGSB‑19.13‑M82 when fully cured and washed; Meets FDA regulation 21 CFR 177.2600 when fully cured and washed; Meets TT‑S‑00230C Class A when fully cured and washed

Applications: Multi‑Purpose

Resistance: Water

Full Cure Time @ Temp.: 24 h @ 77 °F

| SKU | Temp. Range | Color | Specific Gravity | VOC |

|---|---|---|---|---|

| 125-14059 | -45.0 °F - 450.0 °F | Red | 1.42 | 0.5 lb/gal; 4.1 %; 56.0 g/L |

| 125-14055 | -65.0 °F - 450.0 °F | Clear | 1.03 | 54 g/L |

ALEX PLUS® Acrylic Latex Caulks Plus Silicone (PC 18101)

Features:

• Paintable.

• Easy water clean‑up.

Applications: Windows and Door Frames, Eaves, Baseboards, Pipes Molding, Vents, Siding and Trim, Corner Joint

Resistance: Water; Mold; Mildew

Full Cure Time @ Temp.: 24 h @ 77 °F

Specific Gravity: 1.69

VOC: 39.1 g/L

| SKU | Capacity | Color |

|---|---|---|

| 802-18152 | 10.1 oz | White |

All-Purpose 100% Silicone Rubber Sealants

Features:

• Indoor/ Outdoor.

• Minimal shrinkage.

Applications: Around Windows and Doors; Siding and Trim; Gutters and Vents; Molding

Resistance: Water; Shrinkage; Temperature Extremes

Full Cure Time @ Temp.: 24 h @ 77 °F

Specific Gravity: 0.96

VOC: 28.8 g/L

| SKU | Capacity | Color |

|---|---|---|

| 802-08641 | 10.1 oz | Clear |

KWIK SEAL® Kitchen & Bath Adhesive Caulks

Features:

• Paintable.

• Easy water clean‑up.

Applications: Tubs; Shower Stalls; Sinks; Repairing Loose Tiles; Backsplashes; Toilets; Other Cracks & Joints

Resistance: Water; Mold; Mildew

Full Cure Time @ Temp.: 36 h @ 77 °F

Specific Gravity: 1.6

VOC: 32.7 g/L

| SKU | Capacity | Color |

|---|---|---|

| 802-18001 | 5 1/2 oz | White |

Maximum Temperature Thread Sealants

Features:

• Lubricates threads for easy assembly and disassembly.

• Won’t shred or wear like PTFE tape.

• High performance, solvent‑resistant sealant locks and seals metal, tapered pipe threads and fittings.

• Specifically formulated for aluminum, stainless steel, galvanized metal and other inert metals.

Test & Approvals: Mil‑Spec

Temp. Range: ‑65.0 °F ‑ 400.0 °F

Color: White

Applications: Thread

Resistance: Diesel Fuel, Hydraulic Fluid, Leakage, Moisture, Vibration Loosening

Full Cure Time @ Temp.: 24 h@ 72 °F

Specific Gravity: 1.02

VOC: 0.78%

| SKU | Capacity | Packing Type |

|---|---|---|

| 230-56750 | 50 ml | Tube |

Silite® Silicone RTV

Features:

• Single‑component silicone for sealing panels and window plates.

• Bonding and sealing appliance ports.

• Attaching brackets, nameplates, and ceramic tile.

• NSF certified for food equipment and acceptable for use in meat and poultry plants.

Test & Approvals: Elongation and shear tensile strength tested according to ASTM D638; Dielectric strength tested according to ASTM D149; Meets TTS‑00230C; Meets TTS‑001543A; Meets MIL‑A‑46106A, Type I; Flash point measured by TCC; Meets USDA Specifications

Resistance: Weather; Chemicals

Full Cure Time @ Temp.: 7 d @ 77 °F

Specific Gravity: 1.04

| SKU | Temp. Range | Color | Applications |

|---|---|---|---|

| 230-17150 | -60.0 °F - 450.0 °F | Clear | Panels; Window Plates; Appliance Ports; Brackets; Nameplates; Ceramic Tile; Gaskets |

| 230-17130 | -60.0 °F - 600.0 °F | Red | High-Temp Ducting; Ceramic Tile in Pulverizers; Form-In-Place Gaskets |

| 230-17100 | -60.0 °F - 450.0 °F | Clear | Panels; Window Plates; Appliance Ports; Brackets; Nameplates; Ceramic Tile; Gaskets |

Cross-Check™ Torque Seal® Tamper-Proof Indicator Paste

Features:

• Provides a convenient visual method for identification of vibratory loosening or tampering in nuts, bolts, fasteners, and assemblies.

• Highly visible under ambient light and fluorescent under UV light.

• Tamper‑proof torque mark.

• Safe for most surfaces.

Temp. Range: ‑20 °F ‑ 400 °F

Applications: Identifying Loose Nuts, Bolts, Fasteners and Assemblies

Resistance: Tamper Proof

Full Cure Time @ Temp.: 1 to 2 hr

| SKU | Capacity | Packing Type | Color |

|---|---|---|---|

| 253-83318 | 0.05 lb | Tube | Blue |

| 253-83315 | 0.05 lb | Tube | Green |

| 253-83314 | 0.05 lb | Tube | Orange |

| 253-83320 | 0.05 lb | Tube | Pink |

| 253-83316 | 0.05 lb | Tube | Red |

| 253-83319 | 0.05 lb | Tube | White |

| 253-83317 | 0.05 lb | Tube | Yellow |

PLS® 2 Premium Thread & Gasket Sealers

Features:

• Slow‑drying, soft‑setting, non‑toxic, brushable, without grit.

• Permeated with extra fillers to enhance sealing properties.

• Cures by solvent evaporation providing a durable, long‑lasting seal that can be easily disassembled.

Temp. Range: ‑100 °F ‑ 600° F

Applications: Threaded Fittings; Gaskets

Specific Gravity: 1.5

| SKU | Capacity | Resistance |

|---|---|---|

| 296-PB04 | 1/4 pt | Petroleum Fuels; Petroleum Solvents; Propane; Butane; LPG; Water; Cutting Oils |

Soft-Set Thread Sealants

Features:

• Soft‑set, non‑toxic, PTFE paste.

• Remains pliable in cold temperatures.

• NOT for use on oxygen.

Test & Approvals: UL NSF CSA

Temp. Range: ‑100 °F ‑ 600 °F

Applications: Pipes; Joints; Fittings; Hoses

Specific Gravity: 1.53

| SKU | Resistance | Full Cure Time @ Temp. | VOC |

|---|---|---|---|

| 296-SS08 | Gasoline; Kerosene; Petroleum solvents; Diesel fuel; Propane; Butane; Water; Cutting oils | 24 h @ 68 | 27% |

| 296-SS16 | Gasoline; Petroleum; Solvents; Kerosene; Propane; Butane | 24 hrs @ 50 °F | 2.249 lbs/gal |

Cold Weld Compounds

Features:

• Easy to use.

• Nontoxic.

• Made in the USA.

Specific Gravity: 1.9313

VOC: 0.1%

| SKU | Temp. Range | Color | Applications | Resistance | Full Cure Time @ Temp. |

|---|---|---|---|---|---|

| 803-8276 | - 300 °F | Dark Gray | Will bond to virtually any clean, dry surface |

Water; Petroleum; Acid; Chemical | 4 h @ 70 °F |

| 803-8265-S | - 500 °F | Dark Grey | Will bond to virtually any clean, dry surface |

Water; Petroleum; Acid; Chemical | 24 h @ 70 °F |

| 803-8280 | - 500 °F | Dark Grey | Repair Metal | Acid; Water; Solvent; Heat | 24 h @ 70 °F |

Water Weld Compounds

Features:

• WATERWELD can be applied underwater: surfaces to be repaired do not need to be clean and dry.

• “Mushrooms” through and around holes, grabbing the edges to hold securely, then hardening for a permanent seal.

Applications: Repairing Moist Surface and Underwater Applications Gas Tanks, Water and Fuel Cans, Pipe Repair, Ruptured Radiators, Pools and Spas, Gutters and Downspouts and Auto Body Repairs

Resistance: Underwater, Petro, Chemical, Acid-Resistant

Full Cure Time @ Temp.: 20 min

| SKU | Temp Range | Color |

|---|---|---|

| 803-8277 | ‑ 300 °F | Off White |

Loc® Anaerobic Pipe Thread Sealants

Features:

• Anaerobic adhesive provides locking power.

• Ideal for threads in heavy vibration areas such as compressors and reciprocating equipment.

• Seals and locks in the absence of air.

• Do not use on Oxygen service.

• Use PTFE Tape or Oxytite®.

Test & Approvals: Classified by Underwriters Laboratories in USA

Applications: Thread, Compressor

| SKU | Temp Range | Color |

|---|---|---|

| 434-49050 | ‑65 °F ‑ 400 °F | White |

Slic-Tite® Paste Thread Sealants w/ PTFE

Features:

• Do not use on Oxygen service.

• Use PTFE Tape or Oxytite® Paste.

• For sealing water, air, steam, natural gas, LP gas, refrigerants, ammonia, gasoline and oil.

Test & Approvals: USDA Approved for use in federally inspected meat and poultry plants; CSA; NSF; UL; ULC

Applications: Thread

Specific Gravity: 1.48

| SKU | Capacity | Color | Temp. Range | Resistance |

|---|---|---|---|---|

| 434-42029 | 1 pt | White | -50 °F - | Ammonia; Gas; Gasoline; Oil; Water |

| 434-42019 | 1/2 pt | White | -50.0 °F - | Water, Gas, Ammonia, Gasoline, Oil |

| 434-42009 | 1/4 pt | White | -50.0 °F - | Water, Gas, Ammonia, Gasoline, Oil |

Anaerobic Flange Sealants

Features:

• Designed to eliminate movement on rigid assemblies.

• Seals and bonds flanges.

Applications: Gasketing

Resistance: Diesel Fuel; Hydraulic Fluid; Leakage; Moisture; Vibration Loosening

Full Cure Time @ Temp.: 12 h @ 72 °F

Specific Gravity: 1.1

VOC: <3%

| SKU | Temp Range | Color |

|---|---|---|

| 230-51531 | ‑65 °F ‑ 300 °F | Purple |

Anaerobic Gasket Maker

Features:

• Designed to eliminate movement on rigid assemblies.

• High chemical resistance.

• Seals and bonds flanges.

Test & Approvals: NSF

Applications: Gasketing

Resistance: Diesel Fuel; Hydraulic Fluid; Leakage; Moisture; Vibration Loosening

Full Cure Time @ Temp.: 24 h @ 72 °F

Specific Gravity: 1.13

VOC: <3%

| SKU | Temp Range | Color |

|---|---|---|

| 230-51813 | ‑65 °F ‑ 300 °F | Red |

Black RTV Silicone Adhesive Sealants

Features:

• Waterproof and flexible.

• Non‑paintable.

Applications: Seals; Bonds; Repairs; Mends; Secures

Resistance: Oil; Water; Weather; Vibration; Grease

Full Cure Time @ Temp.: 24 h @ 72 °F

Specific Gravity: 1.07

| SKU | Temp Range | Color | VOC |

|---|---|---|---|

| 230-81173 | ‑75.0 °F ‑ 450.0 °F | Black | <4% |

Clear RTV Silicone Adhesive Sealants

Features:

• May be applied to horizontal or vertical surfaces.

• Waterproof and flexible.

Temp. Range: ‑75 °F ‑ 400 °F

Color: Clear

Applications: Seals; Bonds; Repairs; Mends; Secures

Resistance: Oil; Water; Weather; Vibration; Grease

Specific Gravity: 1.01

| SKU | Capacity | Packing Type | Full Cure Time @ Temp. | VOC |

|---|---|---|---|---|

| 230-80855 | 11 oz | Cartridge | 24 h @ 72 °F | 30 g/l |

| 230-80050 | 3 oz | Tube | 24 h @ 72 °F | 30 g/l |

| 230-85913 | 7 1/4 oz | PowerBead™ Can | 24 h | <3% |

Form-A-Gasket® Sealants

Features:

• Brush‑top sealant approved for use in aviation as well as automotive applications.

• Provides an excellent seal to protect against leakage.

Test & Approvals: Conforms to Mil‑S‑45180 D, Type II

Temp. Range: ‑65 °F ‑ 400 °F

| SKU | Resistance | Full Cure Time @ Temp. | Specific Gravity | VOC |

|---|---|---|---|---|

| 230-80015 | Gasoline; Motor Oil; Seawater; Transmission Fluid; Water | 24 h | 1.5 | 11% |

| 230-80011 | Water; Gasoline; Oil; Grease | 24 h @ 72 °F | 1.5 | 12.7% |

| 230-80003 | Gasoline; Motor Oil; Seawater; Transmission Fluid; Water | 24 h | 1.5 | 13.5% |

| 230-80017 | Water; Gasoline; Oil; Grease | 24 h @ 72 °F | 1.1 | 22.2% |

| 230-80016 | Gasoline; Motor Oil; Seawater; Transmission Fluid; Water | 24 h | 1.5 | 11% |

High Performance Thread Sealants

Features:

• Cures rapidly to withstand 10,000 PSI.

• Prevents galling and protects mated threaded areas from rust and corrosion.

• Reliably seals metal, tapered pipe thread fittings.

Resistance: Diesel Fuel, Hydraulic Fluid, Leakage, Moisture, Vibration Loosening

Full Cure Time @ Temp.: 24 h @ 72 °F

Specific Gravity: 1.05‑1.15

VOC: 2.50%

| SKU | Temp Range | Color |

|---|---|---|

| 230-56521 | ‑65.0 °F ‑ 300.0 °F | White |

High Temperature Thread Sealants

Features:

• Lubricates threads for easy assembly and disassembly.

Applications: Oil and Coolant Lines; Fuel Fittings; Rear axle fill plug; Brake and power steering fittings; Head bolts into through holes

Resistance: Leakage, Vibration Loosening, Moisture, Hydraulic Fluid, Diesel Fuel

Full Cure Time @ Temp.: 24 h @ 72 °F

Specific Gravity: 1.21

VOC: <3%

| SKU | Temp Range | Color |

|---|---|---|

| 230-59235 | ‑65.0 °F | White |

High-Temp Red RTV Silicone Gasket

Features:

• Replaces almost any cut gasket by making reliable “formed‑in‑place” gaskets that resist cracking, shrinking and migrating caused by thermal cycling.

Applications: High‑Temp Mechanical Assemblies

Resistance: Aging; Weathering; Thermal Cycling

Full Cure Time @ Temp.: 24 h @ 72 °F

Specific Gravity: 1.05

VOC: 30 g/L

| SKU | Temp Range | Packing Type | Color |

|---|---|---|---|

| 230-81409 | ‑65.0 °F ‑ 650.0 °F | Cartridge | Red |

| 230-81160 | ‑65.0 °F ‑ 650.0 °F | Tube | Red |

| 230-81915 | ‑65.0 °F ‑ 650.0 °F | Automatic Tube® | Red |

| 230-85915 | ‑65.0 °F ‑ 650.0 °F | PowerBead™ Can | Red |

Pipe Joint Compounds

Features:

• Lubricates and seals threaded joints on water, oil and fuel lines.

• No longer available for sale in California due to CA VOC requirements, replacements are 61616 and 61716.

Resistance: Common Shop Fluids

Full Cure Time @ Temp.: 24 h @ 72 °F

Specific Gravity: 1.12

VOC: 14.2%

| SKU | Temp Range | Applications | Color |

|---|---|---|---|

| 230-80045 | ‑65.0 °F ‑ 400.0 °F | Water/Steam/Oil/Fuel Lines | Black |

Pneumatic/Hydraulic Sealants

Features:

• Contains no fillers or particles which could contaminate system fluids, foul valves or clog fine filters and screens.

• Designed for locking and sealing high pressure hydraulic and pneumatic systems.

Resistance: Diesel Fuel; Hydraulic Fluid; Leakage; Moisture; Vibration Loosening

Full Cure Time @ Temp.: 24 h @ 72 °F

Specific Gravity: 1.2

VOC: <4%

| SKU | Temp Range | Applications | Color |

|---|---|---|---|

| 230-54550 | ‑65.0 °F ‑ 300.0 °F | Pneumatic/Hydraulic | Bottle |

Sensor-Safe Blue RTV Silicone Gasket

Features:

• The original Permatex blue makes reliable “formed‑in‑place” gaskets that resist shrinking, cracking and migrating.

• Product cures to a strong, flexible rubber that seals flanges against leakage and resists oil and other shop fluids.

Temp. Range: ‑65 °F ‑ 500 °F

| SKU | Resistance | Full Cure Time @ Temp. | Specific Gravity | VOC |

|---|---|---|---|---|

| 230-80628 | Aging; Thermal Cycling; Weather | 24 h | 1.44 | <3%; <43 g/l |

| 230-80022 | Shrinking; Cracking; Migrating | 24 h @ 72 °F | 1.04 | <4% |

| 230-81860 | Heat; Weather | 24 h | 1.44 | <4% |

The Right Stuff® Gasket Maker

Features:

• Heavy‑bodied, elastomeric rubber provides instant seal.

• Superior flexibility and adhesion accommodates joint movement.

• Instant low pressure seal.

Resistance: Oil; Transmission Fluid

| SKU | Temp. Range | Full Cure Time @ Temp. | Specific Gravity | VOC |

|---|---|---|---|---|

| 230-33694 | -75 °F - 450 °F | 15 min @ 23±2 °C; 50±5% RH | 1.34 | <3% |

| 230-85224 | -75 °F - 450 °F | 15 min @ 23±2 °C; 50±5% RH | 1.34 | <3% |

| 230-25224 | -75 °F - 500 °F | 24 h @ 72 °F | 1.31 | <4% |

Thread Sealants w/ PTFE

Features:

• Seals and resists pressure in air, oil, diesel fuel and hydraulic systems.

• Remains pliable at high and low temperatures.

Resistance: Common Shop Fluids

Specific Gravity: 1.12

VOC: 37.9%

| SKU | Temp Range | Applications | Color |

|---|---|---|---|

| 230-80633 | ‑65.0 °F ‑ 300.0 °F | Air/Oil/Gas/Hydraulic | White |

| 230-80632 | ‑65.0 °F ‑ 300.0 °F | Air/Oil/Gas/Hydraulic | White |

Ultra Series® RTV Silicone Gasket Maker

Features:

• Resists aging, weathering and thermal cycling without hardening, shrinking or cracking.

• Forms a superior bond on oil contaminated metals and maintains outstanding oil resistance.

Test & Approvals: Meets Performance Specs of OE Silicone Gaskets

| SKU | Temp. Range | Color | Full Cure Time @ Temp. | Specific Gravity | VOC |

|---|---|---|---|---|---|

| 230-24105 | -65 °F - 500 °F | Black | 24 h @ 72 °F | 1.26 | <4% |

| 230-81725 | -65 °F - 500 °F | Blue | 24 h @ 72 °F | 1.3 | <4% |

| 230-82195 | -65 °F - 500 °F | Grey | 24 h | 1.47 | <2% |

| 230-82194 | -54 °F - 260 °F | Grey | 24 h @ 72 °F | 1.5 | <2% |

| 230-81878 | - 700 °F | Copper | 24 h @ 72 °F | 1.05 | 7.8% |

| 230-82180 | -65 °F - 500 °F | Black | 24 h @ 72 °F | 1.26 | <4% |

| 230-81724 | -65 °F - 500 °F | Blue | 24 h @ 72 °F | 1.3 | <4% |

| 230-82080 | -65 °F - 500 °F | Black | 24 h @ 72 °F | 1.35 | 3.8% |

| 230-85080 | -65 °F - 500 °F | Black | 24 h @ 72 °F | 1.26 | <4% |

No. 5® Pipe Thread Sealants

Features:

• Soft‑set, slow drying compound which seals, lubricates and protects threaded pipe and fittings.

• Ideal for application with a wide variety of fluids and gases, including potable water application.

• Use on threaded galvanized steel, iron, brass, copper, aluminum, stainless steel, polyethylene, reinforced fiberglass, PVC and CPVC pipes.

Temp. Range: ‑15.0 °F ‑ 400.0 °F

Color: Yellow

Applications: Threaded Galvanized Steel; Iron; Brass; Copper; Aluminum; Stainless Steel; Polyethylene; Reinforced Fiberglass

Resistance: Moisture; Dirt; Dust

Full Cure Time @ Temp.: 24 h @ 77 °F

Specific Gravity: 1.38

VOC: 23%; 317 g/L

| SKU | Capacity | Packing Type | Wt. |

|---|---|---|---|

| 622-25431 | 1 pt | Can | 37.72 lb |

| 622-25300 | 1 qt | Can | 0.18 lb |

| 622-25551 | 1/2 pt | Can | 1.48 lb |

| 622-25631 | 1/4 pt | Can | 2.74 lb |

No. 5® Special Pipe Thread Sealants

Features:

• For use where a low odor sealant with low temperature application is required.

• Non‑staining, soft set compound specifically formulated for use on gas piping or when gas detection equipment is used.

• Recommended for use on threaded galvanized steel, iron, brass, copper, aluminum, stainless steel, polyethylene, fiberglass reinforced and PVC pipe.

Test & Approvals: Conforms to TT‑S‑1732

Temp. Range: ‑15.0 °F ‑ 400.0 °F

Color: Yellow

Applications: Threaded Galvanized Steel; Iron; Brass; Copper; Aluminum; Stainless Steel; Polyethylene; Reinforced Fiberglass; PVC

Resistance: Moisture; Dirt; Dust

Full Cure Time @ Temp.: 24 h @ 77 °F

Specific Gravity: 1.4

VOC: 16%; 160 g/L

Wt.: 3.1 lb

| SKU | Capacity | Packing Type |

|---|---|---|

| 622-26431 | 1 pt | Can |

No. 7 Pipe Thread Sealants

Features:

• Medium‑dry, soft‑set sealant designed for use with lines carrying corrosive chemicals including acids, caustics, alcohol, ethylene glycol, gasoline, and ammonia.

• Recommended for use on threaded galvanized steel, iron, brass, copper, aluminum, and stainless steel pipe.

Test & Approvals: Conforms to AMS‑S‑7916 and TT‑S‑1732

Temp. Range: ‑50.0 °F ‑ 450.0 °F

Color: Black

Applications: Threaded Galvanized Steel; Iron; Brass; Copper; Aluminum; Stainless Steel

Resistance: Moisture; Dirt; Dust

Full Cure Time @ Temp.: 24 h @ 77 °F

Specific Gravity: 1.46

VOC: 28%; 280 g/L

| SKU | Capacity | Packing Type |

|---|---|---|

| 622-17432 | 1 pt | Can |

T Plus 2® Pipe Thread Sealants

Features:

• May be pressurized immediately following application.

• Recommended for use on threaded galvanized steel, iron, brass, copper, aluminum, stainless steel, polyethylene, fiberglass reinforced, PVC, CPVC and ABS pipe.

• Non‑setting multi‑purpose compound which contains PTFE, plus synthetic fibers to create a stronger seal.

Test & Approvals: Conforms to TT‑S‑1732

Temp. Range: ‑15.0 °F

Color: White

Applications: Threaded Galvanized Steel; Iron; Brass; Copper; Aluminum; Stainless Steel; Polyethylene; Reinforced Fiberglass; PVC; CPVC; ABS Pipe

Resistance: Moisture; Dirt; Dust

| SKU | Capacity | Packing Type | Full Cure Time @ Temp. | Specific Gravity | VOC |

|---|---|---|---|---|---|

| 622-23431 | 1 pt | Can | 24 h @ 77 °F | 1.32 | 0% |

| 622-23551 | 1/2 pt | Can | 24 h @ 77 °F | 1.32 | 0% |

Tru-Blu™ Pipe Thread Sealants

Features:

• For refrigeration and industrial applications.

Test & Approvals: Conforms to TT‑S‑1732

Color: Blue

Resistance: Moisture; Dirt; Dust

Specific Gravity: 1.38

| SKU | Temp. Range | Full Cure Time @ Temp. | VOC |

|---|---|---|---|

| 622-31431 | -50.0 °F - 350 °F | 24 h @ 77 °F | 23%; 230 g/L |

| 622-31300 | -50.0 °F - 350 °F | 24 h @ 77 °F | 23%; 230 g/L |

| 622-31551 | -50.0 °F - 350 °F | 24 h @ 77 °F | 23%; 230 g/L |

| 622-31631 | 20 - 400 | — | 23% |

Polyurethane Triple Expanding Foam

Features:

• Seals, bonds, and insulates, filling large and small holes in ceilings, floorboards, concrete or cinder block walls, and around ducts, cables, plumbing areas, and central heating pipes.

Test & Approvals: UL

Applications: Window and door frames; Pipes; Electrical Outlets; Vents; Foundations

Resistance: Waterproof

Specific Gravity: 1.1

| SKU | Temp Range | Full Cure Time @ Temp | Color | VOC |

|---|---|---|---|---|

| 630-0909 | 55° F ‑ 90° F | 24 h @ 77° F | Champagne | < 20% |

| 630-0912 | 55° F ‑ 90° F | 24 h @ 77° F | Champagne | < 20% |

RD PRO® Heat-Resistant RTV Sealants

Features:

• High‑performance industrial sealing and glazing compound that is ideal for use in most OEM and maintenance applications.

• Offers excellent adhesion to most non‑porous building substrates and remains permanently elastic.

Test & Approvals: TT‑S; ASTM; FDA; MIL

Temp. Range: ‑60° F ‑ 500° F

Applications: Oven Belts; Heating Elements in Appliances; Flanged Pipe Joints; Fired Heaters; Access Doors; Drying Vents

Resistance: Chemicals; Heat; Water; Weather

Specific Gravity: 1.02

| SKU | Full Cure Time @ Temp | Color | VOC |

|---|---|---|---|

| 630-0809/OI | 24 h @ 77° F | Red | <3% |

RD PRO® Industrial Grade RTV Sealants

Features:

• High performance sealing and glazing compound that is ideal for use in most OEM and maintenance applications.

• Forms a strong, durable and weather‑resistant seal and provides excellent adhesion to most non‑porous surfaces.

Test & Approvals: TT‑S; ASTM; FDA; MIL

Resistance: Weather; Water; Chemicals; Mildew

| SKU | Temp. Range | Color | Full Cure Time @ Temp. | Specific Gravity | VOC |

|---|---|---|---|---|---|

| 630-0816/OI | -60° F - 400° F | White | 24 h @ 77° F | 1.02 | < 3% |

| 630-0816/6I | -60 °F - 400 °F | Black | 24 h @ 77 °F | 1 - 1.1 | <3%; <40 g/L |

| 630-0816/5I | -60 °F - 400 °F | Gray | 24 h @ 77 °F | 1 - 1.1 | <3%; <40 g/L |

| 630-0826/OI | -60° F - 400° F | Clear | 24 h @ 77° F | 1.02 | < 3% |

| 630-0820 | -60° F - 400° F | Clear | 24 h @ 77° F | 1.02 | < 3% |

| 630-0810 | -60° F - 400° F | White | 24 h @ 77° F | 1.02 | < 3% |

RTV Silicone Sealants

Features:

• Chemically stable and shows little change in physical properties after exposure to sunlight, rain, snow, ozone, temperature extremes and weathering.

• A one‑part ready to use material that shows little change in gunnability at temperatures from ‑80 °F (‑62 °C) to 140 °F (60 °C) permitting the sealant to be applied in any season.

• Can be used for extended periods at temperatures up to 450 °F (232 °C) and for shorter periods at temperatures as high as 500 °F (260 °C).

• Mildew‑resistant.

Color: Clear

| SKU | Capacity | Packing Type |

|---|---|---|

| 425-S00010000 | 8 oz | Aerosol Can |

Contractor RTV Silicone Sealants

Features:

• Interior/Exterior, flexible watertight silicone sealant made with 100% silicone.

• Minimal shrinkage, great for around windows/doors, plumbing, and water pipes.

Temp. Range: ‑49 °F ‑ 302 °F

Specific Gravity: 0.96

| SKU | Color | Resistance | Full Cure Time @ Temp. | VOC |

|---|---|---|---|---|

| 425-WL099110C | Clear | Moisture; Air; Dust; Dirt | 24hr @ 77°F | 0.03 |

| 425-WL099112W | White | Air; Dirt; Dust; Moisture | — | 0.03 |

Silicone Rubber All Purpose Sealants

Features:

• Highly flexible and non‑shrinking 100% silicone sealant offers outstanding protection against water and weather damage.

• Durable and flexible sealant is suited for areas exposed to heavy wear and harsh elements.

• Commonly applied at windows, doors, trim, siding and in many other general purpose applications.

Resistance: Mildew; Moisture

Specific Gravity: 1.06

VOC: 30 g/l

| SKU | Full Cure Time @ Temp | Applications | Color |

|---|---|---|---|

| 425-W11124510 | 24 h | General Purpose | Aluminum |

| 425-W11121010 | 2h h | General Purpose be | Clear |

Stop Gap!® Insulation Foam

Features:

• Can be used to seal and insulate around windows and door frames.

• Dries tack free in 30 minutes.

• Cured product hardens and can be trimmed, shaped, sanded, painted, or stained.

Cure Time: 8 h

| SKU | Temp Range | Packing Type |

|---|---|---|

| 425-WL3333300 | 60.0 °F ‑ 100.0 °F | Aerosol Can |

Threadlockers

Medium Strength Blue Threadlockers

Features:

• All‑purpose, medium strength threadlocker is an excellent choice for everyday use.

• Ideal for all nut and bolt applications 1/4 inch to 3/4 inch (6mm to 20mm).

Test & Approvals: NSF P1

Thread Size: 1/4 in ‑ 3/4 in

Temp. Range: ‑65 °F ‑ 300 °F

Curing Method: Anaerobic

Resistance: Diesel Fuel; Hydraulic Fluid; Leakage; Moisture; Vibration Loosening

| SKU | Fix Cure Time @ Temp | Color |

|---|---|---|

| 230-24210 | 20 min @ 72 °F | Blue |

Permatex® High Strength Red Threadlocker

Features:

• Designed for securing parts that must withstand heavy shock, vibration, or extreme chemical or environmental conditions.

• Suitable for permanently locking studs.

Thread Size: 1/4 in ‑ 3/4 in

Temp. Range: ‑65 °F ‑ 300 °F

Applications: Cylinder Block; Rocker Arm Studs; Ring Gear Bolts; Frame Bolts; Frame Brackets; Hydraulic Press Studs

Curing Method: Anaerobic

Resistance: Chemical/Solvent; Rust/Corrosion

| SKU | Capacity Vol. | Packing Type |

|---|---|---|

| 230-27110 | 10 ml | Bottle |

Permatex® Permanent Strength Red Threadlocker

Features:

• Permanent, high‑strength threadlocker directly applied to fasteners ranging from 3/8” to 1”.

• Designed for securing parts that must withstand heavy shock, vibration, or extreme chemical or environmental conditions.

Temp. Range: ‑65 °F ‑ 300 °F

Applications: Heavy Equipment Bolts; Suspension Bolts; Gear Bolts; Railroad Assemblies; Construction Equipment; Transmission Shaft Bolts

Resistance: Chemical/Solvent; Rust

| SKU | Capacity Vol. | Packing Type |

|---|---|---|

| 230-26210 | 10 ml | Bottle |

High Strength Red Threadlockers

Features:

• Superior to conventional lock washers, nylon inserts and other mechanical devices as Permatex Threadlockers secure the entire fastener assembly against loosening from shock or vibration and they maintain fastener clamp forces.

Test & Approvals: NSF

Thread Size: 3/8 in ‑ 1 in

Temp. Range: ‑65 °F ‑ 300 °F

Curing Method: Anaerobic

Resistance: Diesel; Hydraulic Fluid; Leakage; Moisture; Vibration Loosening

| SKU | Capacity Vol. | Packing Type | Fix Cure Time @ Temp. | Wt. |

|---|---|---|---|---|

| 230-27010 | 10 ml | Squeeze Tube | 15.00 min @ 72 °F | 0.11 lb |

| 230-27150 | 50 ml | Bottle | 20.00 min @ 72 °F | 0.22 lb |

Medium Strength Blue Threadlockers

Features:

• Sturdy, medium‑strength threadlocker provides superior service, as compared to conventional lock washers, nylon inserts and other mechanical devices.

• Locks and seals while preventing parts from loosening due to vibration.

Resistance: Leakage; Vibration Loosening; Moisture; Diesel Fuel; Hydraulic Fluid

| SKU | Temp Range | Curring Method | Thread Size | Fix Cure Time @ Temp. |

|---|---|---|---|---|

| 230-24010 | ‑65 °F ‑ 300 °F | Anaerobic | 1/4 in - 1 in | 15 min @ 72 °F |

| 230-24250 | ‑65 °F ‑ 300 °F | Anaerobic | 1/4 in - 3/4 in | 20 min @ 72 °F |

Permanent Strength Red Threadlockers

Features:

• Superior to conventional lock washers, nylon inserts and other mechanical devices as Permatex Threadlockers secure the entire fastener assembly against loosening from shock or vibration and they maintain fastener clamp forces.

Test & Approvals: NSF, Mil‑Spec

Temp. Range: ‑65 °F ‑ 300 °F

Curing Method: Anaerobic

Resistance: Diesel; Hydraulic Fluid; Leakage; Moisture; Vibration Loosening

| SKU | Thread Size | Fix Cure Time @ Temp. |

|---|---|---|

| 230-26250 | 3/8 in ‑ 1 in | 20 min @ 72 °F |

TAPE PRODUCTS

Duct Tapes

Extra Heavy Duty Duct Tape

Features:

• Consists of polyethylene film over a dense cloth scrim with an aggressive rubber adhesive used for demanding duct tape applications.

Width: 1.88 in

Length: 60 yd

Thickness: 10.7 mil

Adhesion to Steel: 61 oz/in

| SKU | Series | Tensile Strength | Temp Range |

|---|---|---|---|

| 405-051131-06969 | 6969 | 32 lb/in | 200° F |

Duct Tapes 3900

DFeatures:

• Sturdy polyethylene backing resists moisture, prolonging the tape bond in moist or humid environments.

• Low tack roll edges make the tape easier to unwrap and keeps edges cleaner for less surface contamination and wasted tape.

Width: 1.88 in

Length: 60 yds

Thickness: 7.7 mil

Adhesion to Steel: 56 oz/in

| SKU | Type | Tensile Strength | Temp Range |

|---|---|---|---|

| 405-051131-06976 | General Purpose | 22 lb/in | 200° F |

Performance Plus Duct Tapes 8979

Features:

• Leaves behind no sticky residue to clean up.

• Sunlight/UV and Water-Resistant.

| SKU | Length | Width | Thickness |

|---|---|---|---|

| 405-021200-56468 | 2 in | 6.78 in | 12.6 mil |

Silver Duct Tapes 3939

Features:

• Tears easily straight across and down without curling.

• Tack‑free edges.

• Surface can be written on.

Test & Approvals: Meets UL723, HUD, BOCA Codes

Adhesion to Steel: 55 oz/in

Tensile Strength: 25 lb/in

Type: Heavy‑Duty

| SKU | Length | Width | Thickness | Color |

|---|---|---|---|---|

| 405-051131-06975 | 55 m | 48 mm | 9 mil | Silver |

Vinyl Duct Tape 3903

Features:

• Solve your sticky situations ‑ vinyl duct tape with a rubber adhesive sticks well to many substrates.

• Convenient tape unwinds easily off the roll.

• Embossed vinyl backing for easy tear‑by‑hand.

• Conforms well to irregular surfaces.

Width: 2 in

Length: 50 yd

Adhesion to Steel: 15.4 oz/in

Tensile Strength: 12.6 lb/in

Type: General Purpose

| SKU | Series | Color | Thickness | Temp. Range | Wt. |

|---|---|---|---|---|---|

| 405-051131-06984 | 3903 | Gray | 6.3 mil | 200° F | 0.95 lb |

| 405-051131-06992 | 3903 | Red | 6.3 mil | 200°F | 2 1/2 lb |

| 405-051131-06981 | 3903 | White | 6.5 mil | 200° F | 0.95 lb |

| 405-051131-06982 | 3903 | Yellow | 6.5 mil | 200° F | 0.95 lb |

AC10 Duct Tape

Features:

• Polyester (PET) cloth/polyethylene (PE) film with an aggressive pressure sensitive natural rubber adhesive combines to provide a quality utility product.

• Conformable to irregular surfaces.

Thickness: 7 mil

Tensile Strength: 17 lb/in

| SKU | Color | Width | Length |

|---|---|---|---|

| 761-91406 | Silver | 48 mm | 50.2 m |

AC20 Duct Tape

Features:

• One hundred percent Dacron® cloth/polyethylene (PE) film with an aggressive pressure‑sensitive natural rubber adhesive combines to provide a quality utility product.

• Consistent tensile and even tear in both cross and machine direction.

• Excellent conformability to irregular surfaces.

Type: General Purpose

| SKU | Color | Width | Length | Thickness | Adhesion to Steel | Tensile Strength |

|---|---|---|---|---|---|---|

| 761-74977 | Silver | 2 in | 60 yd | 9 mil | 54 oz/in | 19 lb/in |

| 761-91410 | Silver | 48 mm | 54.8 m | 9 mm | 40 oz/in | 18 lb/in |

AC36 HVAC Cloth Duct Tapes

Features:

• General contractor’s duct tape of choice.

• PE coated cloth tape with an aggressive system designed to provide exceptional shear strength for demanding applications, such as HVAC, abatement, weatherproofing, extermination, flex duct connections and all general maintenance needs.

Test & Approvals: UL723 rated, meets HUD and BOCA codes

Width: 48 mm

Length: 54.8 m

Thickness: 11 mil

Temp. Range: 90° F

Tensile Strength: 20 lb/in

| SKU | Series | Color |

|---|---|---|

| 761-4137 | AC36 HVAC Cloth Duct Tape | Silver |

Utility Grade Dacron® Cloth/PE Film Duct Tapes

Features:

• AC20’s aggressive natural rubber adhesive adheres well to a wide variety of surfaces and offers a broad temperature range.

• Polyethylene (PE) coated cloth tape with an aggressive pressure‑sensitive natural rubber adhesive for improved adhesion and shear properties.

• One hundred percent Dacron® cloth/polyethylene (PE) film with an aggressive pressure‑sensitive natural rubber adhesive combines to provide a quality utility product.

• Excellent conformability to irregular surfaces.

Length: 54.8 m

| SKU | Width | Thickness | Tensile Strength |

|---|---|---|---|

| 761-83689 | 48 mm | 8 mil | 18 lb/in |

Utility Grade Duct Tapes

Features:

• All‑purpose duct tape that is perfect for general maintenance applications such as wrapping and sealing, weatherproofing, binding and bundling.

• Conforms to irregular shapes.

Thickness: 7.5 mil

Tensile Strength: 17 lb/in

| SKU | Color |

|---|---|

| 761-87372 | Silver |

Utility Grade PET/PE Duct Tapes

Features:

• Polyester (PET) cloth / polyethylene (PE) film with an aggressive natural rubber pressure sensitive adhesive provides a quality utility product.

• Conformable to irregular surfaces.

| SKU | Tensile Strength |

|---|---|

| 761-91411 | 20 lb/in |

2280 General Purpose Duct Tapes

Features:

• Easy‑tear cloth provides clean, consistent tear by hand.

• Ideal for multiple household, contractor, and maintenance uses.

• Natural rubber adhesive bonds to a wide variety of surfaces.

• Flexible PE cloth backing conforms well to irregular surfaces and shapes.

• Moisture resistant.

Width: 55m

Length: 48mm

Temp. Range: 200° F

Adhesion to Steel: 70 oz/in

| SKU | Series | Color | Tensile Strength | Thickness |

|---|---|---|---|---|

| 573-1087206 | 2280 | Black | 24 lb/in | 9 mil |

| 573-1087205 | 2280 | Red | 24 lb/in | 9 mil |

| 573-1087144 | 2280 | Silver | 24 lbs/in | 9 mil |

307 Utility Grade Duct Tapes

Features:

• Polyethylene coated cloth tape.

• Superior bonding for maintenance and general repair, sealing, bundling, patching and mending.

• Resists twisting and curling.

Width: 48 mm

Thickness: 7 mil

Temp. Range: 200° F

Adhesion to Steel: 65 oz/in

| SKU | Series | Color | Length | Tensile Strength |

|---|---|---|---|---|

| 573-1087253 | 307 | Silver | 27 m | — |

| 573-1087239 | 307 | Silver | 55 m | 22 lbs/in |

Multi-Purpose Duct Tapes

Features:

• Adheres to a wide variety of surfaces.

• Conforms well to irregular surfaces.

• Tears straight, hangs straight, curl resistant.

Temp. Range: 200 °F

| SKU | Series | Color | Width | Length | Thickness | Adhesion to Steel | Tensile Strength |

|---|---|---|---|---|---|---|---|

| 573-1086174 | 396 | Silver | 2 in | 60 yd | 10 mil | 49 oz/in | 23 lb/in |

| 573-1086769 | 394 | Silver | 2 in | 60 yd | 8.5 mil | 40 oz/in | 19 lb/in |

| 573-1086184 | 398 | Silver | 4 in | 60 yd | 11 mil | 49 oz/in | 23 lb/in |

| 573-1086201 | 398 | Black | 48 mm | 55 m | 11 mil | 49 oz/in | 26 lb/in |

| 573-1086178 | 398 | Silver | 48 mm | 55 m | 11 mil | 49 oz/in | 26 lb/in |

Premium Duct Tapes

Features:

• Preferred by professional contractors who demand a consistent, trouble‑free product.

• Outstanding performance over wide range of temperatures.

• Superior tensile strength.

Temp. Range: 200° F

Adhesion to Steel: 50 oz/in

| SKU | Series | Color | Width | Length | Thickness | Tensile Strength |

|---|---|---|---|---|---|---|

| 573-1086150 | 357 | White | 2 in | 60 yd | 13 mil | 43 lb/in |

| 573-1086157 | 357 | Olive Drab | 3 in | 60 yd | 13 mil | 43 lb/in |

| 573-1086141 | 357 | Silver | 48 mm | 55 m | 13 mm | 50 lb/in |

General Purpose Duct Tapes

Features:

• Handles easily, conforms well to irregular surfaces ‑ will not twist or curl during application.

• Good tensile strength, adhesion, and tack.

• General purpose polyethylene coated cloth tape.

Test & Approvals: Meets UL 723

Length: 60 yd

Adhesion to Steel: 50 oz/in

Tensile Strength: 25 lb/in

| SKU | Series | Color | Width | Temp. Range | Thickness |

|---|---|---|---|---|---|

| 573-1086702 | 203 | Black | 2 in | 200° F | 9 mil |

| 573-1086566 | 203 | Red | 2 in | 200° F | 9 mil |

| 573-1086555 | 203 | Silver | 2 in | 200 °F | 9 mil |

| 573-1086567 | 203 | White | 2 in | 200° F | 9 mil |

| 573-1086556 | 203 | Silver | 3 in | 200° F | 9 mil |

Multi-Purpose Duct Tapes

Features:

• Good adhesion and tack.

• Conformable and will not twist or curl during application.

• Excellent adhesion to poly sheeting.

• Natural rubber adhesive bonds strong to surfaces and leaves minimal residue.

• PE Coated cloth backing for strength, conformability, and moisture resistance.

Test & Approvals: Meets UL 723

Length: 60 yd

Temp. Range: 200 °F

Adhesion to Steel: 60 oz/in

Tensile Strength: 25 lb/in

| SKU | Series | Color | Width | Thickness |

|---|---|---|---|---|

| 573-1086550 | 223 | Silver | 2 in | 10 mil |

| 573-1086552 | 223 | Silver | 4 in | 10 mil |

General Purpose Duct Tapes

Features: